PROENERGY, a global peaking-power solutions provider based in Sedalia, Missouri, released a new 48-MW aeroderivative gas turbine designed to quickly respond to gaps in power supply and demand. The PE6000 model was unveiled as a finale to PROENERGY’s annual user conference, held in Houston, Texas, earlier this month. The company explained that each PE6000 begins with an overhauled engine core from a CF6-80C2, a GE aircraft engine design commonly found in Boeing 747s and some other planes. “The concept of matching a flight engine core with aeroderivative parts was born and executed through a collaboration between a major European utility and PROENERGY,” it said. “Our in-house engine and repair expertise was a critical enabler of the PE6000 program,” Rob Andrews, PROENERGY senior vice president of Operations, said in a statement. “We developed other key areas of expertise in system and component design, materials engineering, and manufacturing excellence to progress our R&D [research and development] program both internally and in collaboration with key partners and suppliers. The result is a product manufactured proudly with every new part to PROENERGY design and specification.” Aeroderivative gas turbines are often used for peaking power due to their ability to start quickly and reach full power in a short time. Other options commonly used for peaking power include reciprocating internal combustion engines, pumped storage hydropower, battery energy storage systems, demand response schemes, among other things. In addition to the rapid response times aeroderivatives offer, benefits provided by these gas turbines include high reliability and availability, and relatively clean, cheap, and high-quality power with a small plant footprint. Aeroderivatives are very well-suited to complement the intermittency of renewable power resources such as solar and wind energy. PROENERGY invested seven years and $115 million in R&D, manufacturing, and infrastructure for its PE6000 program. The company has manufactured two PE6000 turbines (Figure 1) to date. One unit is installed in a WattBridge generating facility in Houston and has more than 100 starts and 750 hours of runtime. The company said the second unit is ready for testing. Six additional units are scheduled for validation in WattBridge facilities in the future.

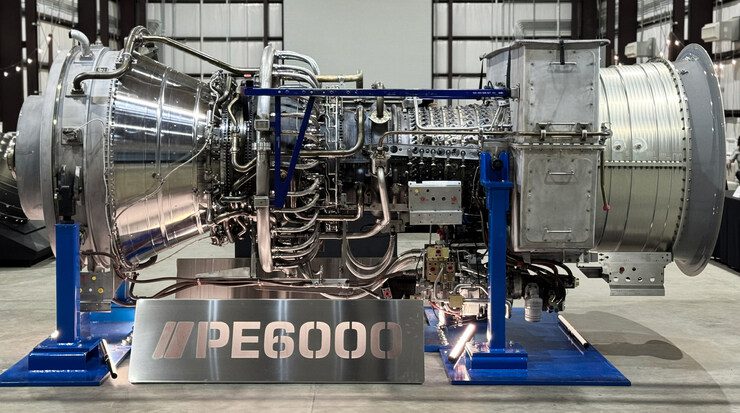

1. PROENERGY assembled a complete PE6000 aeroderivative turbine at its Sedalia campus using components made by the company. Courtesy: PROENERGY PROENERGY has painstakingly built its capabilities in power plant construction, equipment repair, overhaul services, outage response, and turnkey plant operation solutions since its founding in 2002 by President and CEO Jeff Canon. The company has long specialized in services for the LM6000 and LM2500 gas turbine platforms. In 2018, however, though cost and market conditions were optimal, a standardized LM6000 power plant package was not available. To fill the market gap, PROENERGY designed a fully engineered and standardized modular peaking plant that could be delivered turnkey and perform reliably with an absolute cost advantage. It rolled out the solution, “PowerFLX,” that year, furnishing customers with a single source point—from inception through commercial operation—for building out PowerFLX plants. At the same time, it established a dedicated power generating company, WattBridge, to develop, own, and operate PowerFLX plants. WattBridge completed its first power facility based on a standardized LM6000 plant design in January 2021, just weeks ahead of Winter Storm Uri. HO Clarke, a 288-MW peaker in Houston is equipped with six LM6000PC units, running at average heat rate of 9,725 Btu/kW. The plant was recognized in 2022 as a POWER Top Plant award winner. The design has since been replicated in an expanding fleet purpose-built to furnish the volatile Texas grid with crucial peaking power. The new PE6000 offers another option to would-be plant owners. “We aim to deliver exactly what the world needs right now: low-cost, dispatchable generation,” Canon said in a statement. “Our company was founded on finding a better way; for us, this meant giving flight engines new life and becoming an OEM [original equipment manufacturer] for aeroderivative turbines.” —Aaron Larson is POWER’s executive editor (@POWERmagazine). POWER Senior Associate Editor Sonal Patel contributed to this article.

Read the full article here